Controlling a Global Giant, Hyundai Case Study in South Korea

Hyundai Motor Co., Ltd., is the one of the largest manufacturer of automobiles and is also a significant player in this market. It is a South Korean multinational automotive manufacturer headquartered in Seoul. They are broadening their territory and leading the globalization of the Korean automotive industry. Chung Ju-Yung founded the Hyundai Engineering and Construction Company in 1947.

Hyundai Motor Company was later established in 1967, and the company's first model, the Cortina, was released in cooperation with Ford Motor Company in 1968. After 1967, this company has grown to produce an annual capacity of 1.6 million units. Hyundai Motor prepared a foundation to grow into a global enterprise through effectively unifying management of global operation sites in America, China, India and Europe. The company employs about 75,000 people worldwide. Hyundai vehicles are sold in 193 countries through some 5,000 dealerships and showrooms around the world.

To keep the company running competitively, an essential factor was to effectively monitor the production line and status of operation of the company’s automobile factories worldwide. Hyundai Motor decided to integrate the process control and video surveillance systems to be able to be monitored at any time by the authorized personnel from the control room in Korea. An IP-based video surveillance system was introduced, that took advantage of the company’s existing global IT infrastructure.

Before introduction of the command control network, the video solution, process control and video surveillance were operated by different departments that was very troublesome. For example, in order to find the cause of a downturn in the operation data from an overseas factory, video data was requested and then the recording of the incident had to be searched and found. This process took a lot of time as finding the cause of the incident and providing immediate response was not possible and caused delays.

The problem

These features were definitely necessary, because Hyundai Motor has approximately 500 network cameras distributed throughout the Hyundai Motor’s network, that are controlled by Camera Software from America, China, India and Europe, so the system needed to manage several inputs simultaneously.

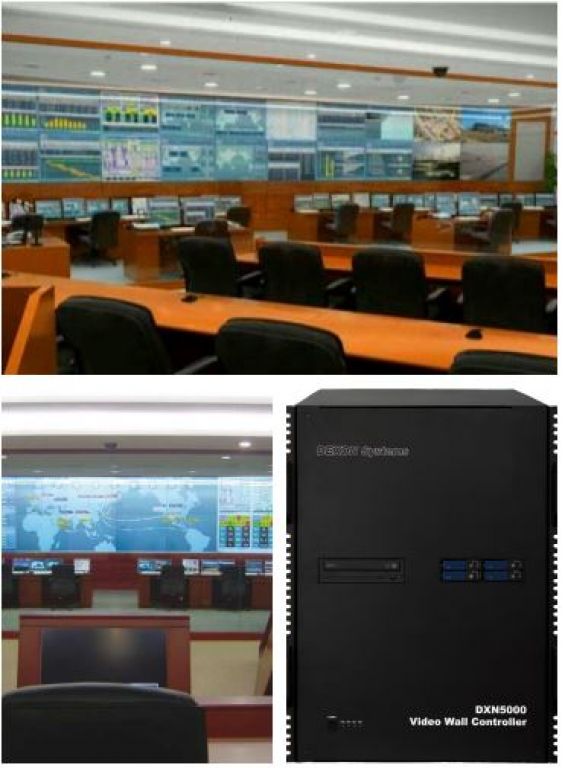

The installation contains 24 pieces of Hitachi 70” LCOS Display Cubes that are driven by DEXON’s DXWall Video Wall Controller. The integrator found this controller to be the best solution for this project. “It’s durable, reliable, designed for 24/7 operation and it is best in the market for displaying high-definition live video windows in freely definable layouts.”

Operation result

Real-time monitoring and speed control of the production volume are now possible for all the Hyundai Motor factories worldwide. Video is accessed on demand by the global control room in Korea, resulting a very efficient system where reinforcement of the current network could be avoided. Incidents and issues can now be addressed at once, thus highly improving the work process.

The representative of the System Integrator company, Mr. Alex Ha said: “The DEXON’s controller proved it’s versatility again. These controllers are ideal for such projects like this, because they are remotely controllable. Besides they can handle many different kind of inputs easily and the operators from different locations can control the information displayed through the network or other interfaces like a web browser.”